Salutations!

I have been receiving a great deal of requests for a tutorial on how I did the weathering on my Wild Lands table. Here’s a quick rundown:

I painted this terrain set using inks primarily. They are perfect for painting MDF terrain for two reasons; first, they go through an airbrush with no need for dilution. Second, the MDF is porous and absorbs the paint/ink cutting drying time.

|

|

Color’s used:

Daller Rowney – Burnt Umber 223

Liquitex Ink – Carbon Black

Citadel (GW) – Mournfang Brown

Vallejo Game Color – Hot Orange 72009

Vallejo Model Color – Light Orange 70911

Vallejo Surface Primer – Gray

Materials Used:

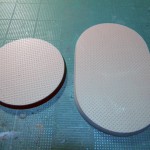

Egg foam

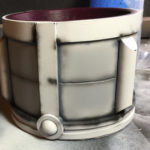

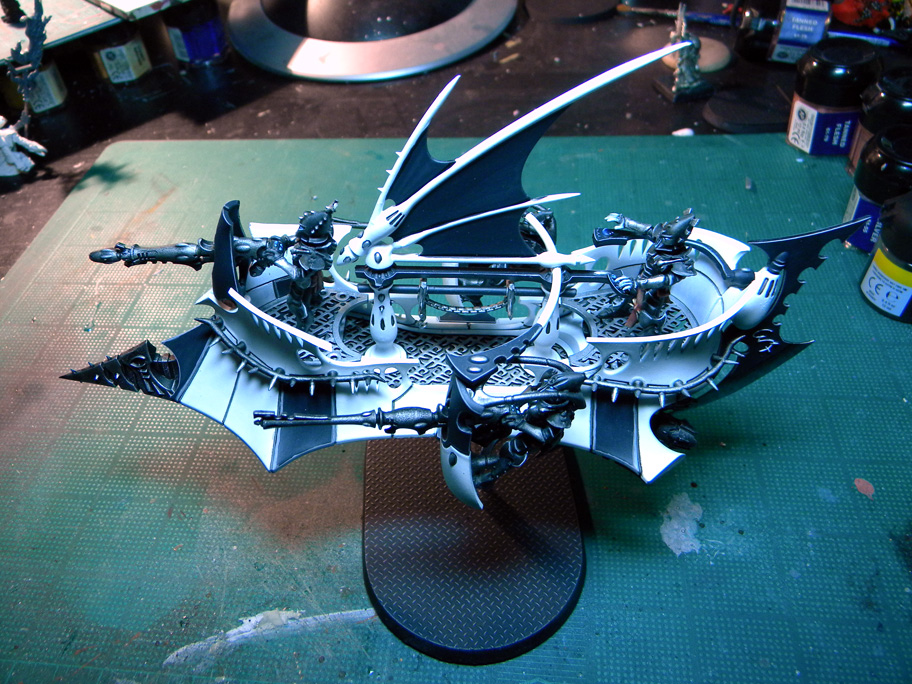

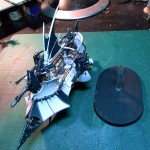

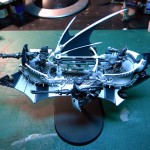

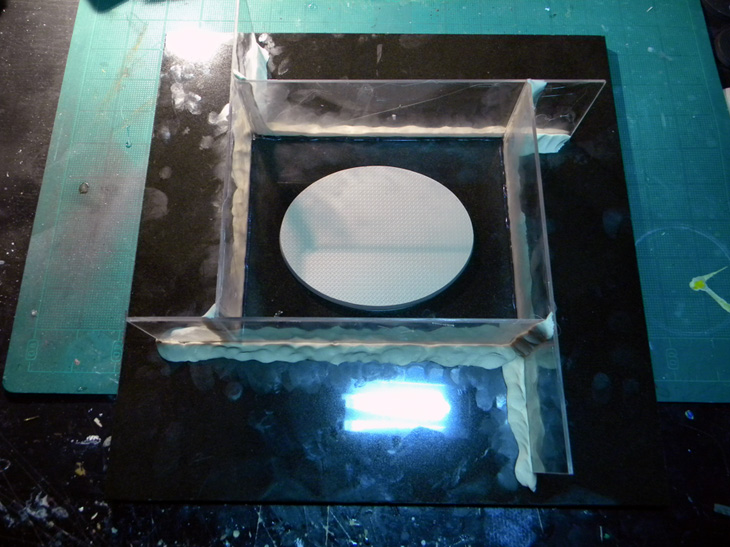

I currently don’t have any new terrain pieces prepped for painting so I’m using a cast of the dice box I made for my Necrons a few years ago. It was sitting around and looked like it would make a pretty cool cistern for my table.

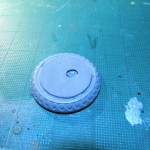

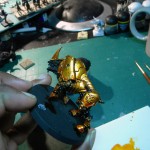

Step I – The box was primed gray. Since the cup is made out of resin it lacks the nice quick drying quality of MDF, I used a hairdryer to speed up the process. In fact I did the same thing with the MDF terrain. Really helps to keep stuff rolling.

Step II – All the cracks & crevices were airbrushed in black. It looks heavy at the start but once you start weathering you’ll be glad for it.

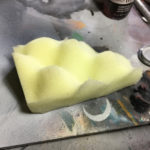

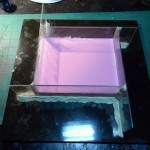

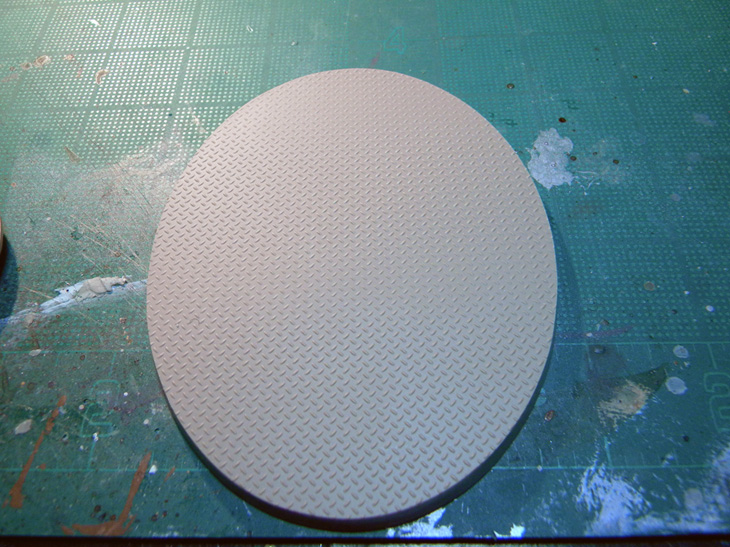

Step III – I took a piece of egg foam I had sitting around and cut it into pieces about 1 by 1.5 inches wide. Then, using my fingers I pulled plugs out of the flat side to make the surface uneven. It’s important to pull the edges as you don’t want a ‘square’ sides on the sponge. I like using the egg foam for this process as the ridged side have little finger holds.

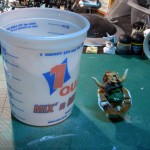

Step IV – Break out the burnt umber. I used condiment cups for this but a palate is fine. Dip the textured end in the ink and place a few practice dabs on your palate to get full coverage on the sponge. These practice dabs also help to control the amount of ink on the sponge as it can be heavier then you expect and you don’t want to make any mistakes on your piece.

|

|

|

|

|

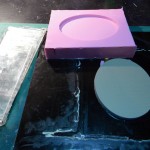

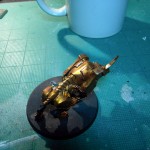

Step V – Lightly dab the surface you want weathered. I turn the sponge around to add to the randomness of the ‘splatter’ look. As this surface is not porous, I had to use the hairdryer between panels. I decided to go with a heavy rust/corrosion look on the cup. I went lighter on the buildings.

After the large panels were done I noticed I had a great deal of ‘white space’ along the edges. I ripped up a smaller sponge and used that to get ink in the corners/edges as that’s where rust would accumulate first. The smaller sponge was also used to color the rest of the box and to create some areas where the ink is applied heavily. These heavy splotches are needed for the next step.

Step VI – Rip up an new small piece of sponge. You can also wash the smaller piece you made for the umber phase. Using the Mournfang Brown, add new splotch patches over the umber. You want to aim to cover the areas (not completely) where the umber was heavy as these spaces will represent your rust areas.

Step VII – These last steps go fast. Repeat the process you used for Step VI but this time using the Hot Orange followed by the Light Orange. Cover the brown with patches of orange but again not completely. You want the previous color to show underneath. The key to this phase is to go easy. Less is more.

And that’s it! I painted the rest of the cup with some glow effects and called it a day. The weathering process took about 10-15 minutes to complete and 20-25 minutes for the whole paint job. You’ll kick yourself at how easy this is to do in the end. Feel free to shoot me any questions.

Shawn G. (SoI)